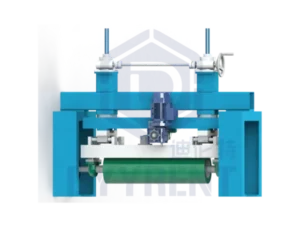

Polishing roller mechanism principle

The polishing roller mechanism of this equipment is arranged in a wide and longitudinal direction. It can polish the workpiece with high-speed rotation and slap on the workpiece according to the lifting and lowering of the abrasive material, and can swing left and right for processing. The surface of the workpiece is polished and wire-drawn, and straight lines appear on the surface. texture effect.

|

Technical Specifications |

|||

|

Schematic Diagram |

|

|

|

|

Model |

800SL |

800SLL |

800SSLL |

|

Effective working width |

850mm |

||

|

Deburring thickness |

0.5-80mm |

||

|

Fixed mode |

Vacuum fixation/Magnet fixation (optional) |

||

|

Minimum machining dimension |

≥30*30 Magnet fixed table |

||

|

≥50*50*1 Vacuum fixed table |

|||

|

Feed rate(Frequency conversion adjustable) |

0.5-9m/min |

||

|

Belt speed(Frequency conversion adjustable) |

2.2-11m/sec |

||

|

Polishing roller speed (Frequency conversion adjustable) |

8-19r/min |

||

|

Swing speed (Frequency conversion adjustable) |

9-20r/sec |

||

|

Polishing roller motor |

5.5kw |

5.5kw 2PCS |

|

|

Swing motor |

0.37kw |

||

|

Belt motor |

11kw |

11kw 2PCS |

|

|

Conveyer motor |

1.5kw |

||

|

Bench servo lifting motor |

None |

1kw |

|

|

Compressed air requirement |

0.6MPa |

||

|

Machine weight |

2000kg |

2500kg |

3000kg |

Features

Polishing roller mechanism principle

The polishing roller mechanism of this equipment is arranged in a wide and longitudinal direction. It can polish the workpiece with high-speed rotation and slap on the workpiece according to the lifting and lowering of the abrasive material, and can swing left and right for processing. The surface of the workpiece is polished and wire-drawn, and straight lines appear on the surface. texture effect.

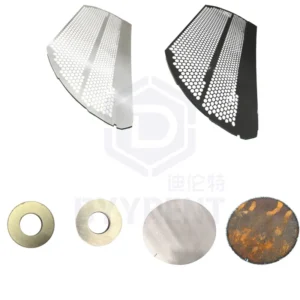

Sample Display

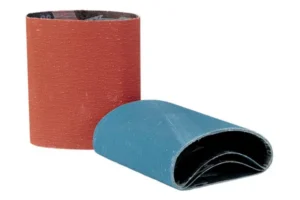

Accessories