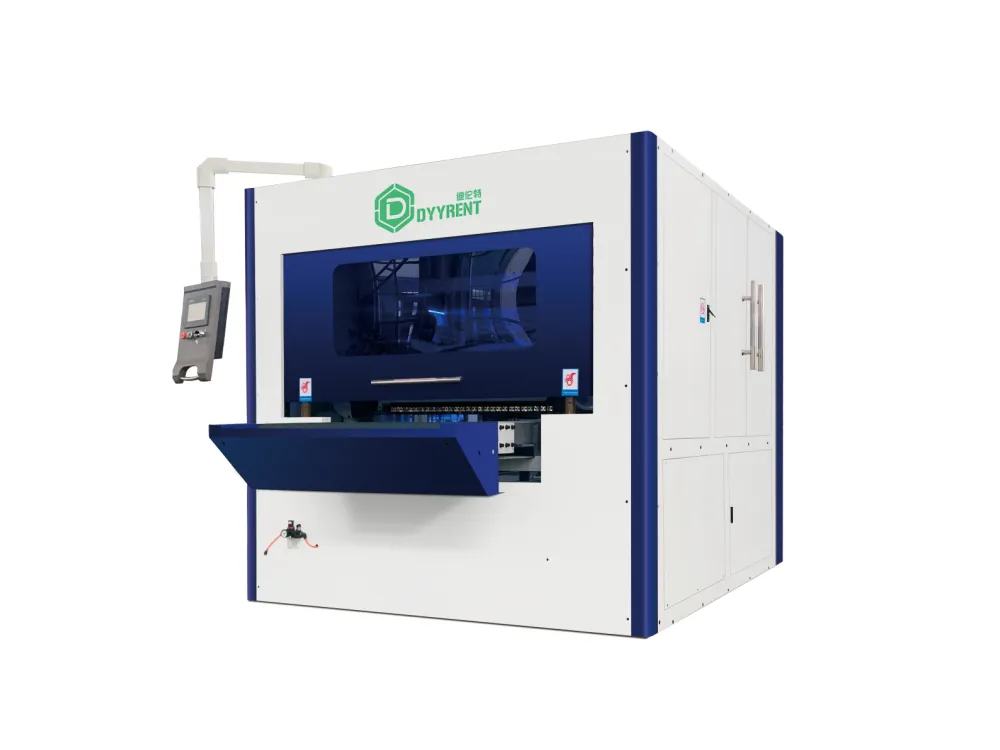

Hammer head slag removal function

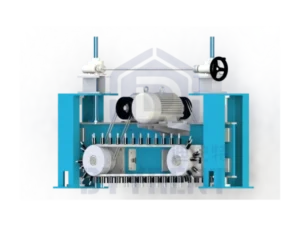

Slag removal structure: Two belt-mounted hammer heads rotate left and right at high speed with each other, and run horizontally to knock the slag on the surface of the workpiece to make the slag fall off.

|

Technical Specifications |

|||

|

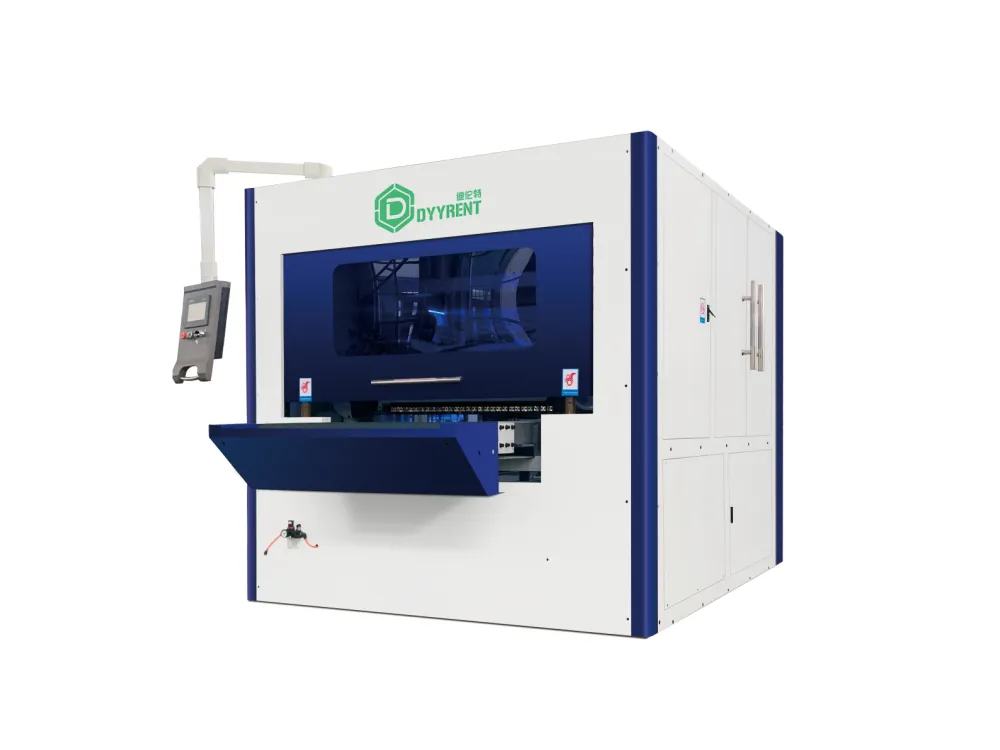

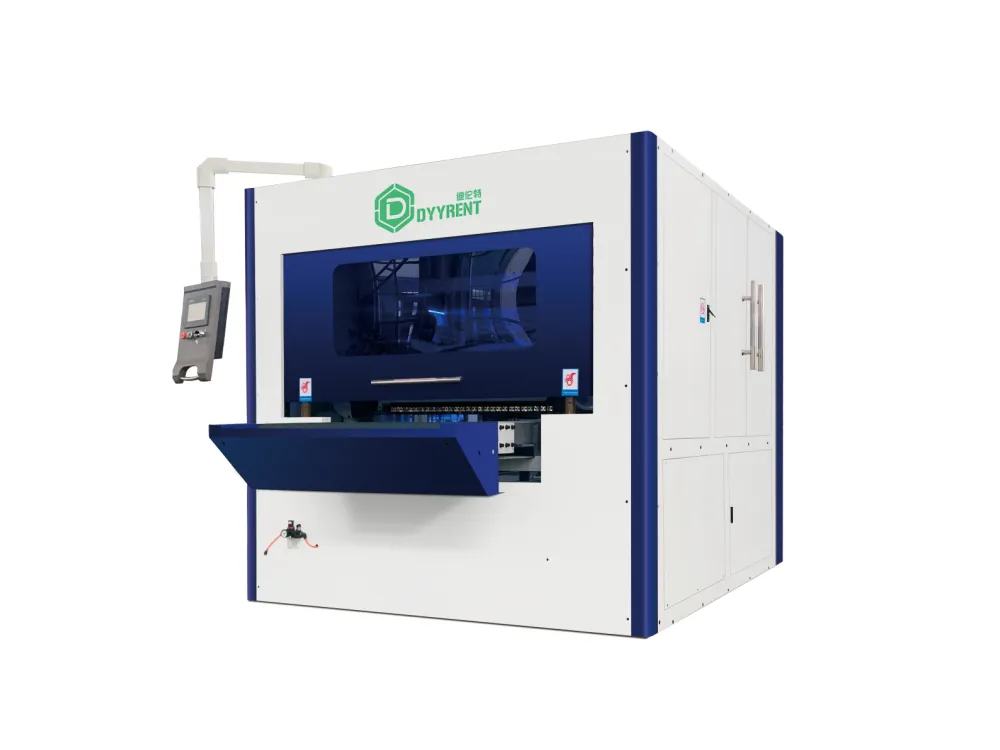

Schematic Diagram |

|

|

|

|

Model |

800JS |

800JSS |

800JSG |

|

Effective working width |

850mm |

||

|

Deburring thickness |

0.5-80mm |

||

|

Fixed mode |

Vacuum fixation/Magnet fixation (optional) |

||

|

Minimum machining dimension |

≥30*30 Magnet fixed table |

||

|

≥50*50*1 Vacuum fixed table |

|||

|

Feed rate(Frequency conversion adjustable) |

0.5-9m/min |

||

|

Belt speed(Frequency conversion adjustable) |

2.2-11m/sec |

||

|

Revolution speed (Frequency conversion adjustable) |

|

8-19r/min |

|

|

Brush speed (Frequency conversion adjustable) |

9-20r/sec |

||

|

Thousand Wire Roller Quantity |

4 |

||

|

Revolution machine |

1.5kw |

||

|

Roller brush motor |

2.2kw 2PCS |

||

|

Belt motor |

11kw |

11kw 2PCS |

11kw |

|

Conveyer motor |

2.2kw |

||

|

Slag removal motor |

2.2kw 2PCS |

||

|

Roller brush lifting motor |

|

0.37kw |

|

|

Bench servo lifting motor |

1kw |

||

|

Compressed air requirement |

0.6MPa |

||

|

Machine weight |

2400kg |

2600kg |

3600kg |

Features

Hammer head slag removal function

Slag removal structure: Two belt-mounted hammer heads rotate left and right at high speed with each other, and run horizontally to knock the slag on the surface of the workpiece to make the slag fall off.

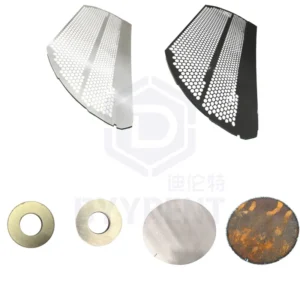

Sample Display

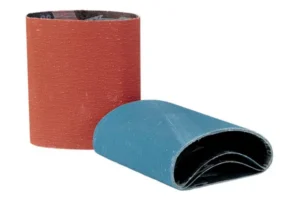

Accessories