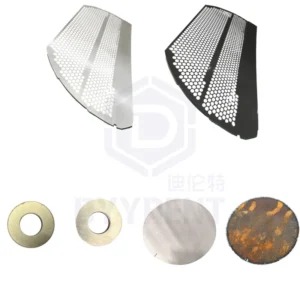

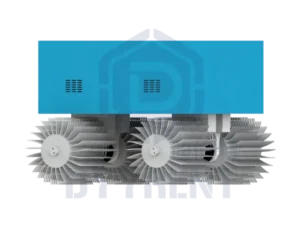

Principle of chamfer mechanism

The grinding mechanism of this equipment is a roller brush mechanism. Driven by the revolution shaft, each roller brush rotates at high speed, and rotates 360° to beat the workpiece, effectively removing the sharp edges of the surface contour of the workpiece, and forming a smooth and beautiful chamfering effect.

|

|

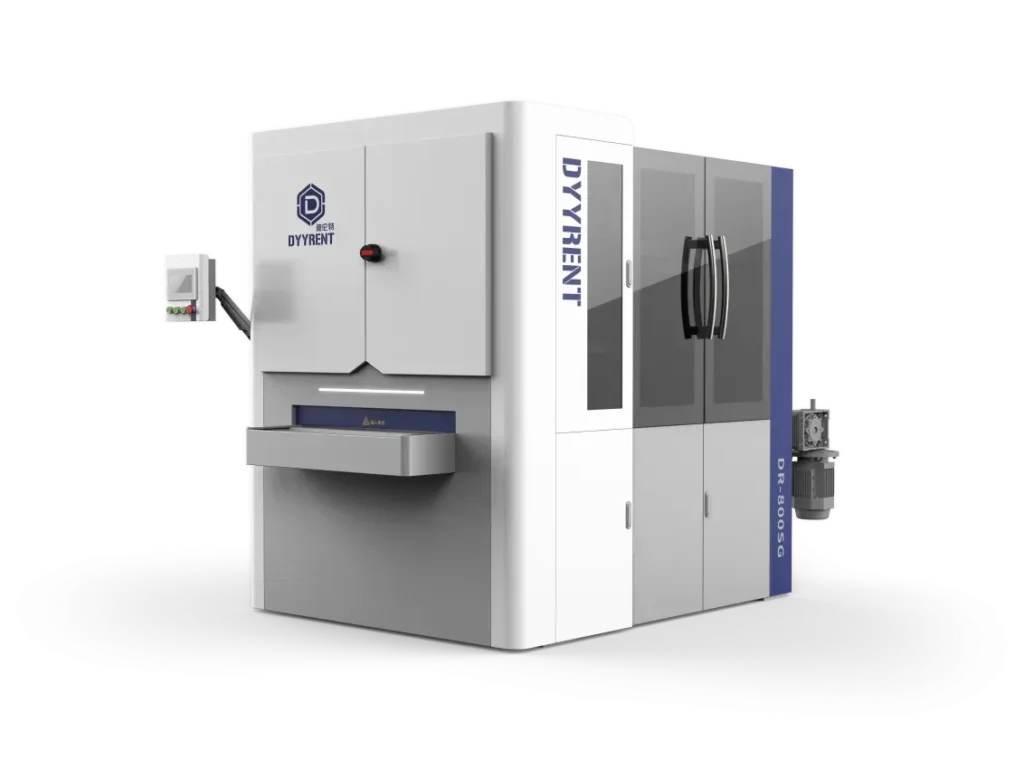

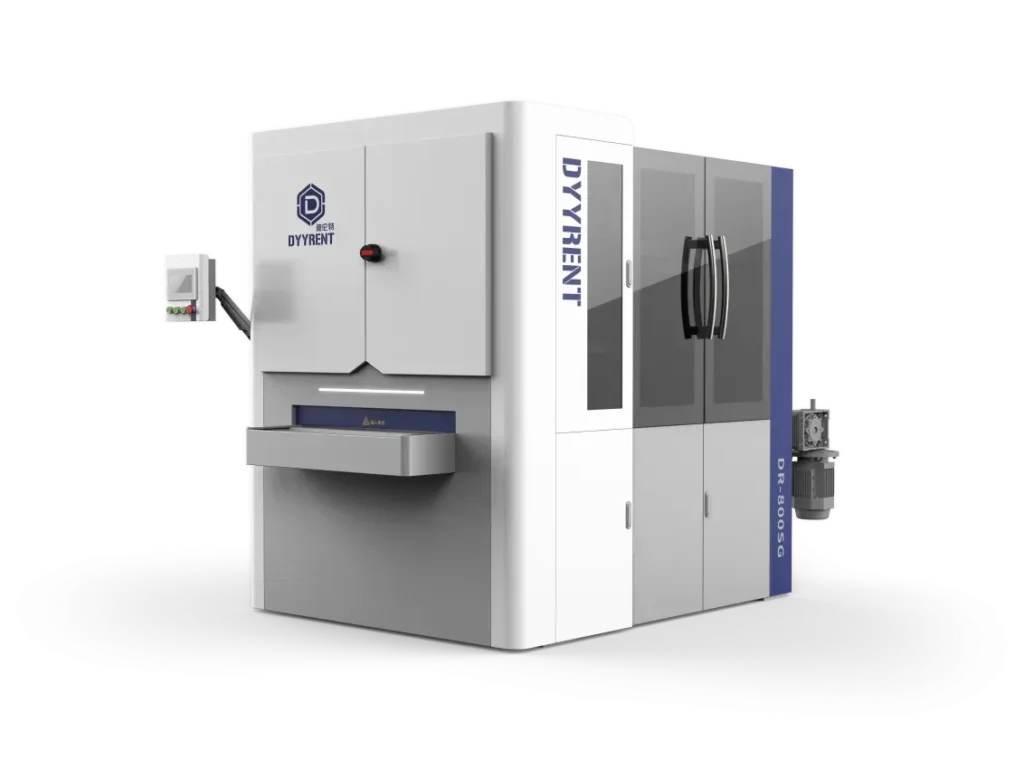

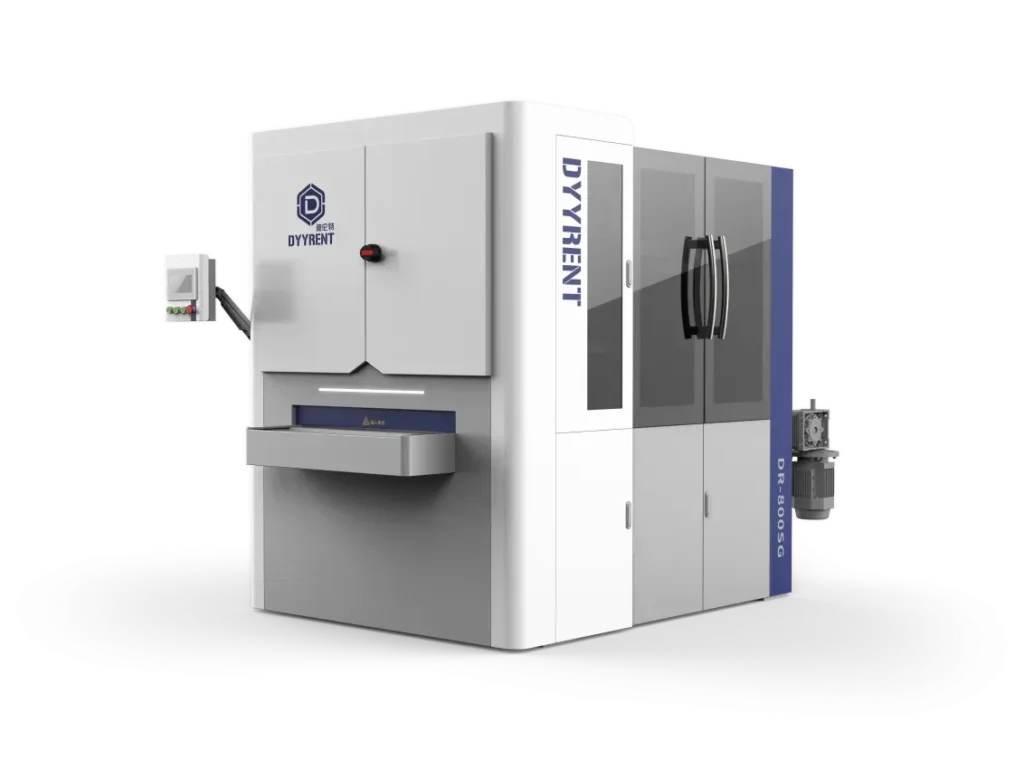

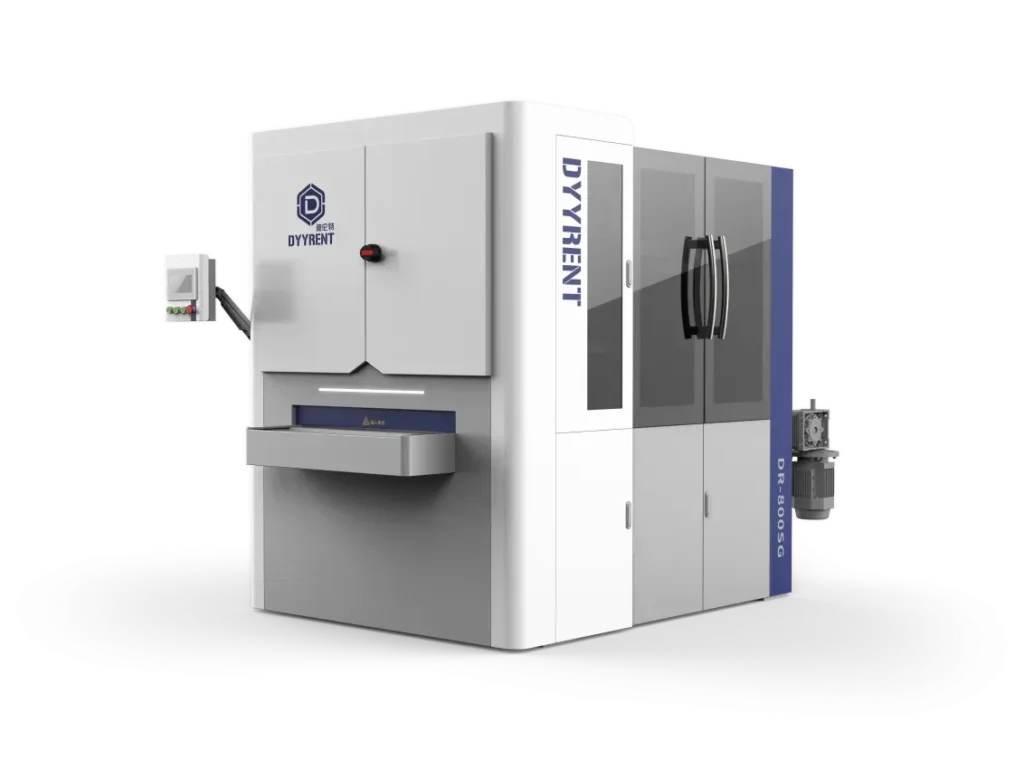

Abrasive belt plus roller brush model The equipment is a combination model of aAbrasive belt and universal roller. It is mainly used to process the surface of workpieces and achieve surface drawing, descaling, polishing, chamfering and other processing of metal sheets. The melting point and burrs generated during laser cutting, plasma cutting, flame cutting, etc. can be removed in all directions. The processing process is safe and reliable, so that the workpiece can achieve perfect results. This equipment is a through-type processing equipment, which can realize wire drawing, polishing, descaling, burr and other processing on the surface of metal sheets through the abrasive belt station. The universal roller removes burrs and chamfers around the material and in the holes. |

|||

|

Technical Specifications |

||||

|

Schematic Diagram |

|

|

|

|

|

Model |

600G |

600SG |

600SGS |

600SSG |

|

Effective working width |

650mm |

|||

|

Deburring thickness |

0.5-80mm |

|||

|

Fixed mode |

Vacuum fixation/Magnet fixation (optional) |

|||

|

Minimum machining dimension |

≥30*30 Magnet fixed table |

|||

|

≥50*50*1 Vacuum fixed table |

||||

|

Feed rate(Frequency conversion adjustable) |

0.5-9m/min |

|||

|

Belt speed(Frequency conversion adjustable) |

None |

2.2-11m/sec |

||

|

Revolution speed (Frequency conversion adjustable) |

8-19r/min |

|||

|

Brush speed (Frequency conversion adjustable) |

9-20r/sec |

|||

|

Thousand Wire Roller Quantity |

4 |

|||

|

Revolution machine |

1.5kw |

|||

|

Roller brush motor |

2.2kw 2PCS |

|||

|

Belt motor |

None |

7.5kw |

7.5kw 2PCS |

|

|

Conveyer motor |

1.5kw |

|||

|

Roller brush lifting motor |

0.37kw |

|||

|

Bench servo lifting motor |

None |

1kw |

||

|

Compressed air requirement |

0.6MPa |

|||

|

Machine weight |

2600kg |

2800kg |

3100kg |

3100kg |

|

Nanjing Dyyrent Machinery Technology Co, Ltd. Web: https://daix181.sg-host.com/ Phone : +86 153 6607 2206 Email:grace@dyyrent.com |

||||

Principle of chamfer mechanism

The grinding mechanism of this equipment is a roller brush mechanism. Driven by the revolution shaft, each roller brush rotates at high speed, and rotates 360° to beat the workpiece, effectively removing the sharp edges of the surface contour of the workpiece, and forming a smooth and beautiful chamfering effect.