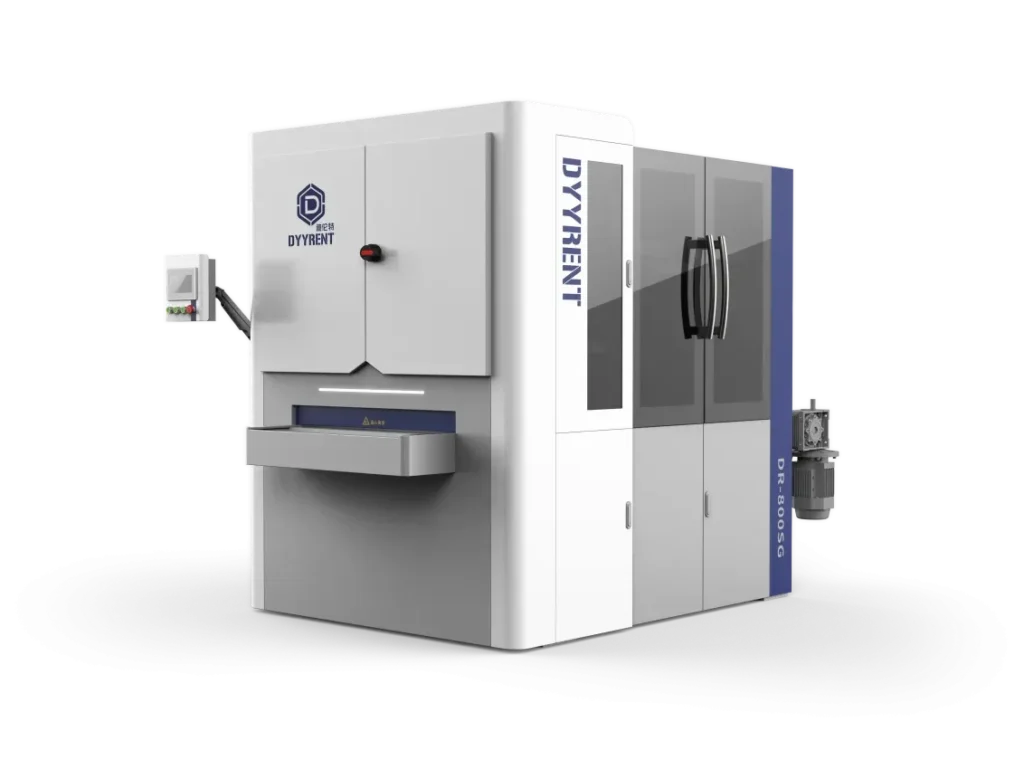

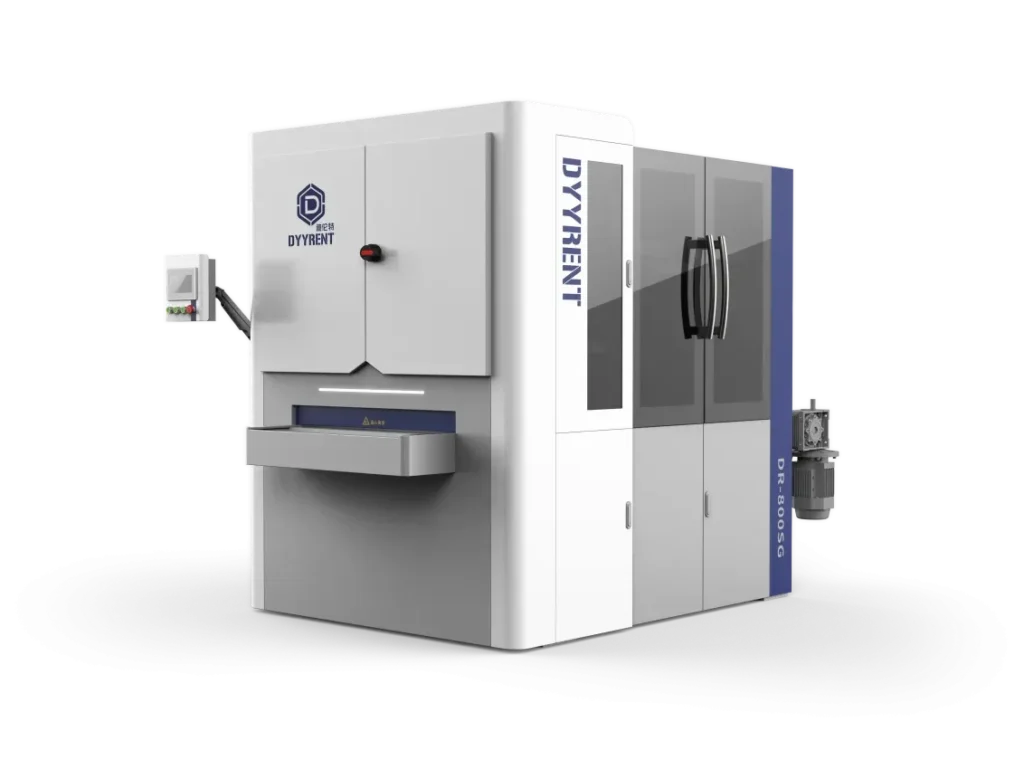

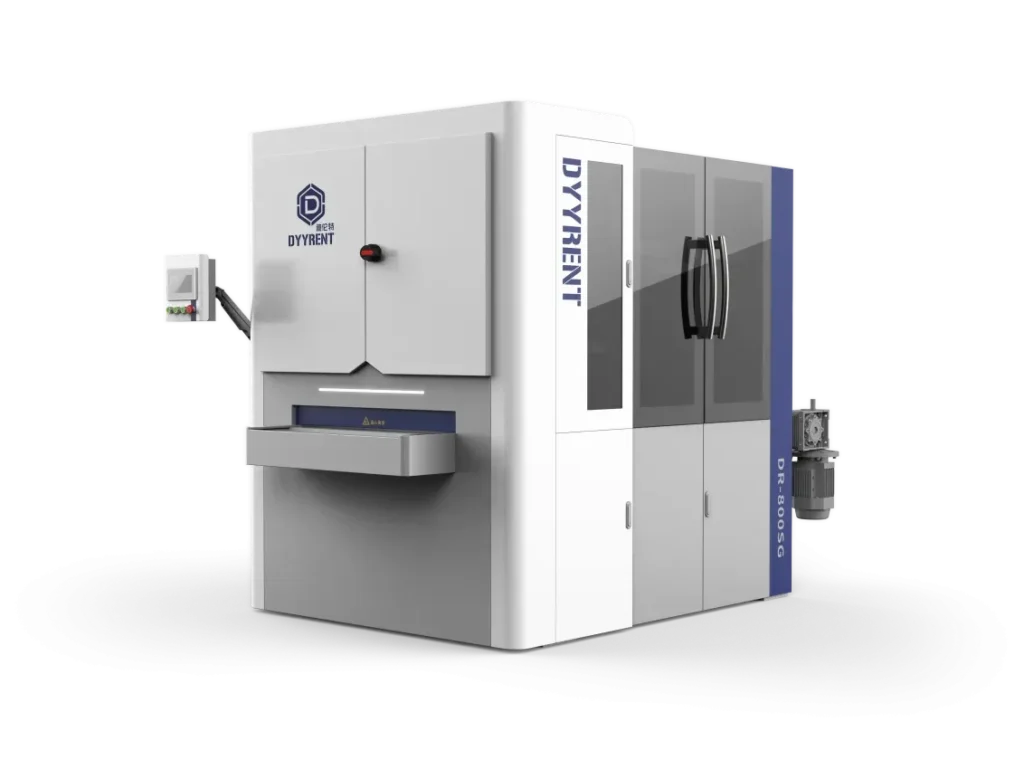

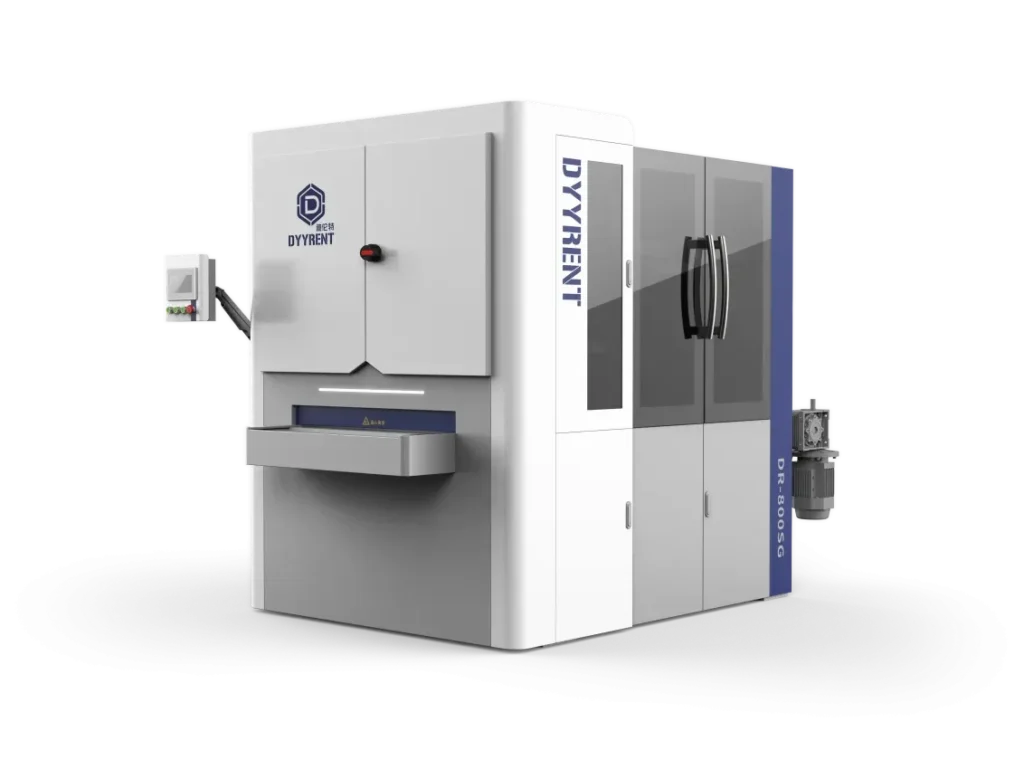

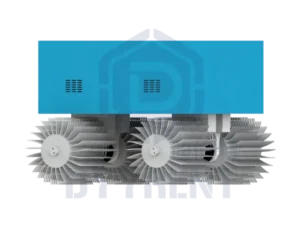

Principle of chamfer mechanism

The grinding mechanism of this equipment is a roller brush mechanism. Driven by the revolution shaft, each roller brush rotates at high speed, and rotates 360° to beat the workpiece, effectively removing the sharp edges of the surface contour of the workpiece, and forming a smooth and beautiful chamfering effect.

|

Technical Specifications |

||||

|

Schematic Diagram |

|

|

|

|

|

Model |

1300G |

1300SG |

1300SGS |

1300SSG |

|

Effective working width |

1350mm |

|||

|

Deburring thickness |

0.5-80mm |

|||

|

Fixed mode |

Vacuum fixation/Magnet fixation (optional) |

|||

|

Minimum machining dimension |

≥30*30 Magnet fixed table |

|||

|

≥50*50*1 Vacuum fixed table |

||||

|

Feed rate(Frequency conversion adjustable) |

0.5-9m/min |

|||

|

Belt speed(Frequency conversion adjustable) |

None |

2.2-11m/sec |

||

|

Revolution speed (Frequency conversion adjustable) |

8-19r/min |

|||

|

Brush speed (Frequency conversion adjustable) |

9-20r/sec |

|||

|

Thousand Wire Roller Quantity |

6 |

|||

|

Revolution machine |

2.2kw |

|||

|

Roller brush motor |

2.2kw 4PCS |

|||

|

Belt motor |

None |

22kw |

22kw 2PCS |

|

|

Conveyer motor |

3kw |

|||

|

Roller brush lifting motor |

0.37kw |

|||

|

Bench servo lifting motor |

None |

1kw |

||

|

Compressed air requirement |

0.6MPa |

|||

|

Machine weight |

3500kg |

3800kg |

4000kg |

4000kg |

Features

Principle of chamfer mechanism

The grinding mechanism of this equipment is a roller brush mechanism. Driven by the revolution shaft, each roller brush rotates at high speed, and rotates 360° to beat the workpiece, effectively removing the sharp edges of the surface contour of the workpiece, and forming a smooth and beautiful chamfering effect.

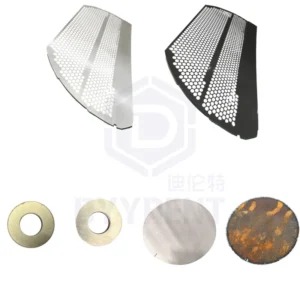

Sample Display

Accessories