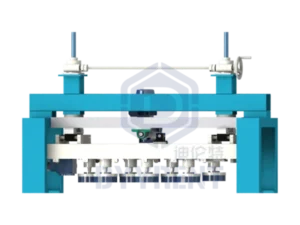

Disc brush mechanism principle

The grinding mechanism of this equipment is a disk brush mechanism. The disk brush mechanisms are placed in parallel. Driven by the revolution axis, each disk brush rotates left and right at high speed and beats the workpiece, effectively removing the sharp edges of the surface contour of the workpiece and forming a smooth and beautiful chamfering effect.

|

Technical Specifications |

|||

|

Schematic Diagram |

|

|

|

|

Model |

800SP |

800SPP |

800PPP |

|

Effective working width |

850mm |

||

|

Deburring thickness |

0.5-80mm |

||

|

Fixed mode |

Vacuum fixation/Magnet fixation (optional) |

||

|

Minimum machining dimension |

≥30*30 Magnet fixed table |

||

|

≥50*50*1 Vacuum fixed table |

|||

|

Feed rate(Frequency conversion adjustable) |

0.5-9m/min |

||

|

Belt speed(Frequency conversion adjustable) |

2.2-11m/sec |

|

|

|

Disk brush swing speed (Frequency conversion adjustable) |

8-19r/min |

||

|

Disk brush rotation speed (Frequency conversion adjustable) |

9-20r/sec |

||

|

Number of disk brushes |

5 |

||

|

Disk brush motor |

5.5kw |

||

|

Disk brush swing motor |

0.37kw |

||

|

Belt motor |

11kw |

||

|

Conveyer motor |

2.2kw |

||

|

Bench servo lifting motor |

1kw |

||

|

Compressed air requirement |

0.6MPa |

||

|

Machine weight |

2500kg |

2700kg |

3000kg |

Features

Disc brush mechanism principle

The grinding mechanism of this equipment is a disk brush mechanism. The disk brush mechanisms are placed in parallel. Driven by the revolution axis, each disk brush rotates left and right at high speed and beats the workpiece, effectively removing the sharp edges of the surface contour of the workpiece and forming a smooth and beautiful chamfering effect.

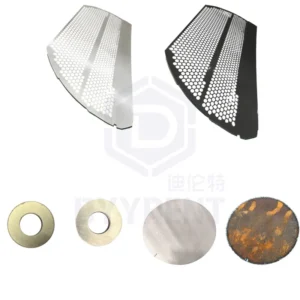

Sample Display

Accessories